It’s been a while, but I finally got around to starting the process of making apple cider. We harvested a huge amount in September and made lots of apple products, but there was so much left over I decided that I would try my hand at apple cider. Of course, there’s big difference between deciding something and doing something. At the time, I tried to figure out what equipment I would need and it was too confusing so I put it aside. Then this weekend I watched this video and decided I was over-thinking it.

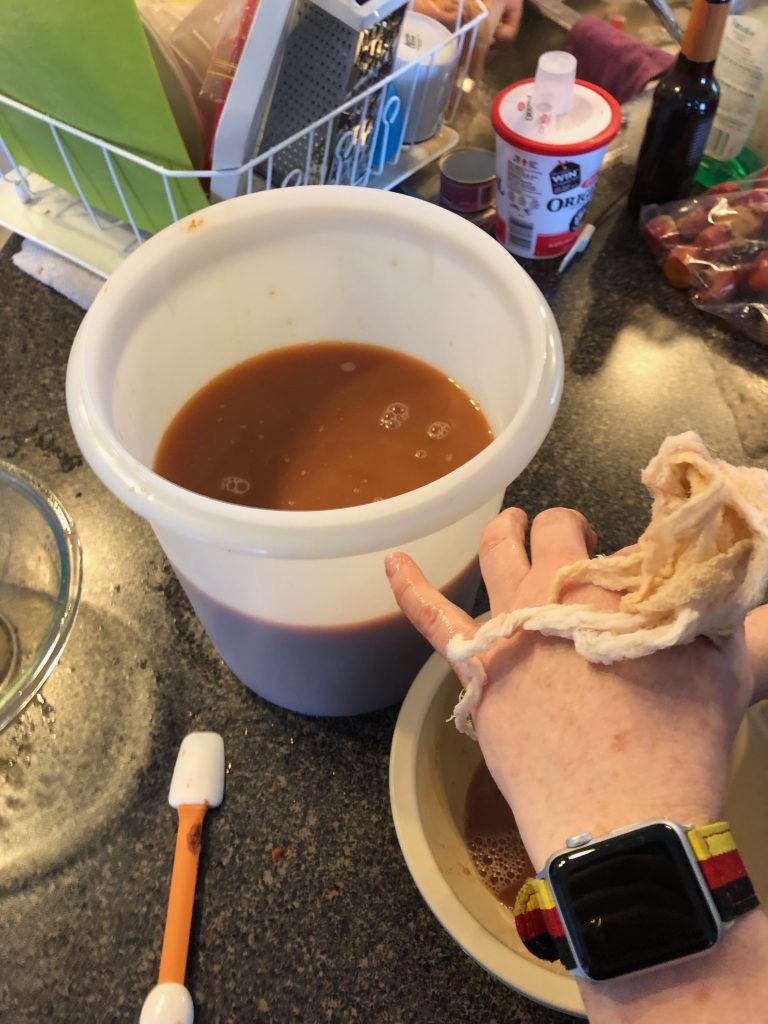

The biggest question was how to juice the apples. Buy a juicer? Use the blender? Food processor? The juicer that the guy in the video is using is this one, which is $200. I decided to try using the food processor (the attachment on Tammy’s Bosch mixer). It’s not a big one, but as it turns out, it does a pretty good job. The next thing to figure out was straining the pulp. What came out of the food processor was like applesauce. First I tried a strainer and a bowl that fit inside it to create a press, but Tammy pulled out some cheesecloth and that was much better.

It took a while. One person working the food processor, two squeezing the cheesecloth bags and one person “roving”: chopping apples, helping out where needed.

The test bag of apples (with the strainer press) yielded about 1/2 litre of juice, so since I had 18 bags in total, I expected 9 litres (2 gallons) of juice. Tammy and I went to Grapes to Glass and the fellow there was very helpful, setting me up with the necessary bits and bobs, including a 3 gallon carboy.

It turned out that the cheesecloth filtering was much more efficient. We were using one of Mom’s old Tupperware bins for collecting the juice, and it was filled after only 13 of the 18 bags.

Eyeballing it, it’s probably more than 2.5 gallons, so we called it quits and tossed the rest of the apples in the green bin! ♻️ Then Tammy had some insane laughter as we started to clean up… there were applesauce and apple seeds everywhere.

I have put the Campden tablets in (which turned the juice from ruddy brown to a apple-cidery yellowish colour) and tomorrow the yeast goes in.

Updated on Day 2 (Tuesday)

This afternoon, I took the next step. First thing was that I noticed there was about an inch of sediment in the bottom of the tub. That, combined with the fact that there is only about an inch of breathing room between the top of the juice and the lip of the tub, convinced me to siphon off the juice prior to adding yeast. I sanitized the equipment with the Sani-Brew powder that we got yesterday and rinsed everything out. Then Tammy helped as I transferred the clear(er) juice to the carboy, leaving the “applesauce sludge” behind. That sludge is now being drained ready for pasteurization and eventual consumption…

We then added 2 cups of white and 2 cups of brown sugar as well as 2 tsp of the yeast nutrient, and one packet of Lalvin EC1118 wine yeast. The plan is to now leave the tub open for a couple of days before transferring it back into the carboy for aging.

At this point, I’m sure we’ve already screwed things up. 😄

Updated on Day 4 (Thursday)

The photo-cider has now had a couple of days in the tub. There was a thin layer of foam on the top, but there was no risk of it foaming over. I sanitized all of the gear and then Tammy and I siphoned the liquid out of the tub and into the carboy. I used distilled water to:

- Fill the siphon to get it going,

- Top up the carboy to reduce the amount of air in it, and

- Fill the bubbler.

It’s now bubbling away.

The next steps will be figuring out if we have enough bottles and how to go about capping. I can order a capper and bottle caps and likely will. If we don’t have enough bottles, then I’m sure we can get some more.

🍻

Updated on April 27

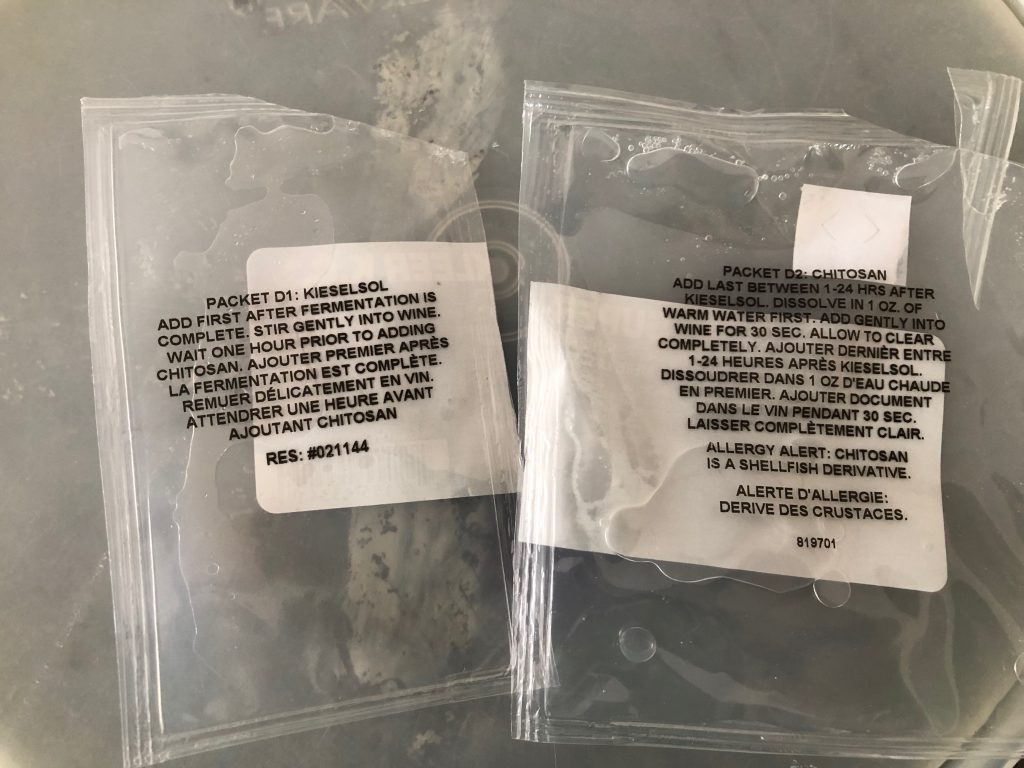

We’ve been waiting for the cider to clarify, and we tried some dilute gelatine last weekend, with limited success. So today we went to Grapes to Glass and got some clarifying agent.

Within hours, the cider had really transformed.

Updated on May 5

The job’s done. This morning, Tammy and I siphoned the cider into the Tupperware bucket, added about 2-3 tablespoons of crystalline Xylitol and bottled it.

Tammy put one Cooper’s Carbonation Drop in each of the small and large bottles, and two in the big bottle and the growler. We will see exactly how fizzy they end up.

Now to wait. Probably July to August.

“Biickert Breweryers” Specializing in exotic Ciders!!

Looking good!!